Warehouse Automation ROI Calculator: The Real Numbers Behind Picking, Packing, and Payback Periods

Every warehouse manager has heard the pitch: automate and save millions. But the question that actually matters—how long until this investment pays for itself?—rarely gets a straight answer. The global warehouse automation market is on track to exceed $30 billion in 2026, yet only 12% of warehouses have fully automated their picking operations. The gap between hype and adoption comes down to one thing: ROI clarity.

The State of Warehouse Automation in 2026

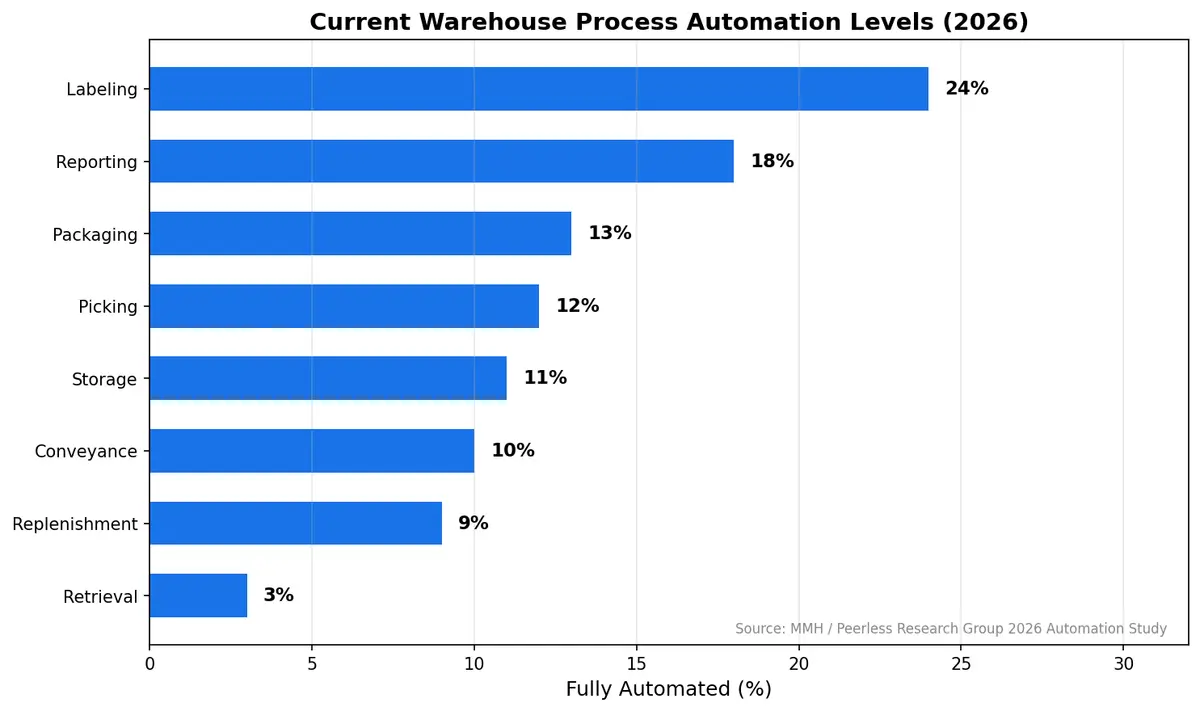

The 2026 MMH Automation Study, conducted by Peerless Research Group across 120+ facilities, reveals a surprising truth: most warehouse processes remain largely manual. Labeling leads full automation adoption at just 24%, followed by reporting at 18% and packaging at 13%. Picking—the most labor-intensive and costly operation—sits at only 12%.

These numbers tell a clear story. Despite $21 billion invested globally in warehouse automation in 2023 alone, most operations are still in the early innings. The opportunity for ROI is massive precisely because so few have captured it yet.

Payback Periods: What the Data Actually Shows

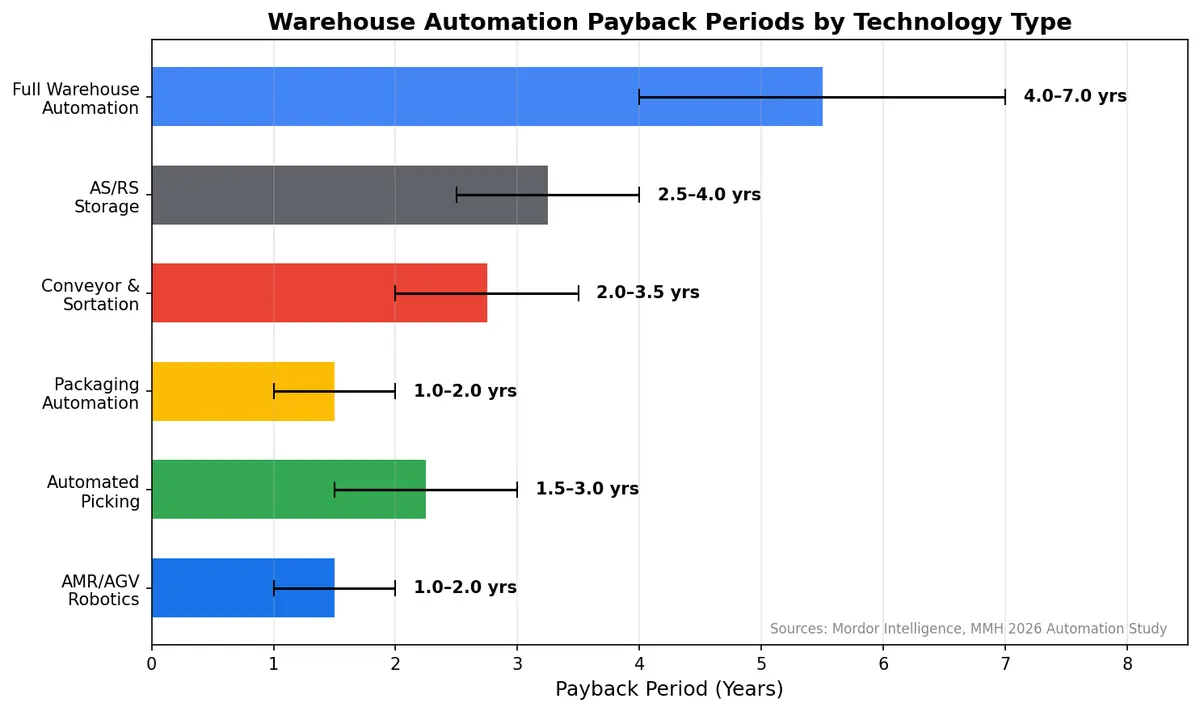

Not all automation investments are created equal. Payback periods vary dramatically depending on the technology, scale, and operational context. Here's what current deployments are showing:

Autonomous Mobile Robots (AMRs) deliver the fastest returns. According to Mordor Intelligence, AMRs achieve payback in under 24 months with ROI above 250% in live deployments. The Robotics-as-a-Service (RaaS) model has accelerated this further—ABI Research projects 1.3 million RaaS installations by 2026, generating over $34 billion in revenue.

Picking automation typically pays back in 1.5 to 3 years, depending on order volume and labor costs. Given that picking accounts for roughly 55% of total warehouse labor hours, even modest efficiency gains compound quickly.

Packaging automation offers one of the tightest payback windows at 1 to 2 years, driven by material waste reduction, consistent pack quality, and reduced damage claims.

Full warehouse automation (AS/RS, conveyor systems, integrated WMS) requires the longest horizon at 4 to 7 years, but delivers the highest absolute returns for high-volume operations processing 10,000+ orders daily.

The Hidden ROI Factors Most Calculators Miss

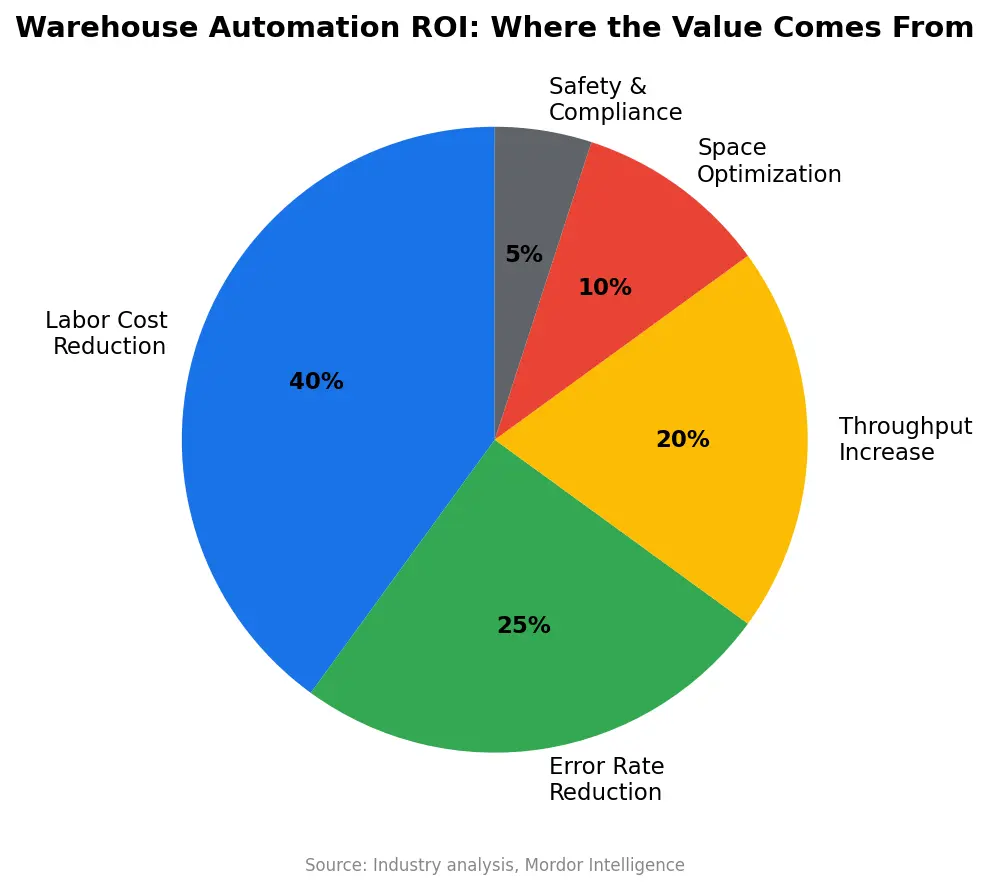

Traditional ROI models focus on labor replacement—and that's a mistake. Labor savings are real (warehouse labor accounts for up to 50% of total operating costs), but they're only part of the equation.

Error Rate Reduction

Manual picking error rates typically run between 1% and 3%. Automated systems consistently achieve 99.9%+ accuracy. For a warehouse shipping 5,000 orders per day, reducing errors from 1.5% to 0.1% eliminates 70 daily mis-picks. At an average correction cost of $25–$50 per error (return shipping, restocking, replacement), that's $640,000 to $1.28 million in annual savings that never shows up in a basic labor-hours calculator.

Throughput and Capacity

Automation doesn't just do the same work faster—it unlocks capacity that didn't exist. AMRs and goods-to-person systems can increase picking throughput by 200–300%, meaning the same square footage handles two to three times the volume. When the alternative is leasing additional warehouse space at $8–$12 per square foot annually, the avoided real estate cost alone can justify the investment.

Safety and Compliance

OSHA reports that warehousing and storage had a total recordable incident rate of 5.5 per 100 workers in recent years. Automation reduces repetitive strain injuries, forklift incidents, and ergonomic risks. Workers' compensation savings and reduced absenteeism contribute 3–5% of total ROI—small in percentage but significant in absolute dollars for large operations.

A Practical ROI Framework

Here's a simplified framework for estimating warehouse automation ROI:

Step 1: Calculate current labor cost per order Total warehouse labor cost ÷ total annual orders = cost per order

Step 2: Estimate automation impact

- Picking: 40–60% labor reduction

- Packing: 30–50% labor reduction

- Sorting/conveyance: 50–70% labor reduction

Step 3: Add hidden savings

- Error reduction: Current error rate × orders × average correction cost

- Throughput gain: Additional orders handled × margin per order

- Space optimization: Freed square footage × lease rate

Step 4: Calculate payback Total investment ÷ (annual labor savings + hidden savings) = payback period

Most mid-size warehouses processing 2,000–10,000 orders per day find their total payback period falls between 18 and 36 months when all factors are included—significantly shorter than the 3–5 year estimates based on labor savings alone.

Why WMS Integration Makes or Breaks Automation ROI

The MMH study found that average facility size among respondents was 137,054 square feet with an average workforce of 1,095 people. At that scale, automation without intelligent orchestration creates new bottlenecks instead of eliminating old ones.

A warehouse management system that integrates with automated picking, packing, and conveyor systems doesn't just coordinate workflows—it optimizes them in real time. Dynamic slotting, wave planning, and predictive maintenance all depend on a WMS layer that speaks natively to your automation hardware. Without it, you're running a Ferrari with a paper map.

The Bottom Line

Warehouse automation ROI is real, measurable, and—for most operations—faster than expected. The key is looking beyond labor replacement to capture the full value: error reduction, throughput gains, space optimization, and safety improvements. With AMRs paying back in under two years and the RaaS model eliminating massive upfront capital requirements, the barrier to entry has never been lower.

The facilities that will win in 2026 aren't the ones with the most robots. They're the ones with the smartest integration between automation hardware and warehouse management software—where every pick, pack, and shipment is orchestrated for maximum efficiency.

Want to see how CXTMS integrates with warehouse automation to maximize your ROI? Contact us for a personalized demo.