From Visibility to Intelligence: Why 97% of Supply Chain Leaders Say Tracking Alone Is Not Enough

FedEx just dropped a bombshell on the logistics industry. Their first-ever Future of Logistics Intelligence Report, released February 10, 2026, surveyed hundreds of global logistics leaders and found that 97% say visibility alone is no longer enough to stay competitive. The era of "we can see our shipments" is over. The era of intelligence has begun.

The Visibility Plateau

Here's the paradox: supply chain visibility has never been better. According to the FedEx report, 97% of leaders say they can track every shipment end-to-end, and 94% have unified visibility across all shipment modes. The supply chain visibility software market itself is valued at over $3 billion in 2026 and growing at double-digit rates.

Yet despite all this tracking capability, disruptions still blindside organizations. Delays still cascade. Customer complaints still pile up. The problem isn't that companies can't see what's happening — it's that seeing isn't the same as knowing what to do about it.

The Intelligence Gap: Seeing vs. Predicting vs. Acting

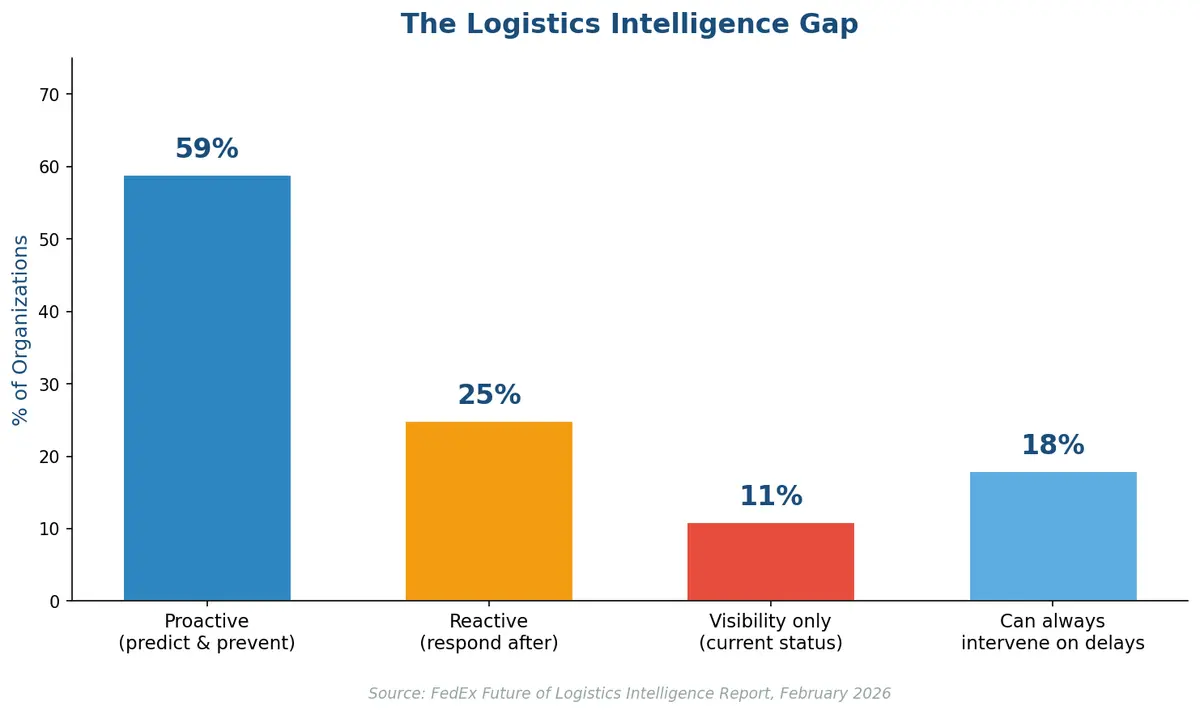

The FedEx report quantifies this gap with striking clarity:

- Just 59% of organizations use data proactively to predict and prevent issues

- 25% still use logistics data reactively — responding only after problems occur

- 11% use data only for visibility into current issues, with no forward-looking analysis

- Only 18% say their teams can always intervene when shipments are delayed

Think about that last number. Fewer than one in five organizations can consistently act on the disruptions they detect. The rest are watching problems unfold in real time with no playbook to respond.

This is the intelligence gap. It's the distance between a dashboard full of green and red dots and a system that tells you which red dot matters, why it happened, and what to do next.

Why Consumers Are Forcing the Shift

The pressure isn't just internal. Consumer expectations are accelerating the need for logistics intelligence at every touchpoint. According to the same report:

- 36% of decision-makers say consumers prioritize reliable delivery windows above all else

- 34% cite end-to-end shipment tracking as the top consumer demand

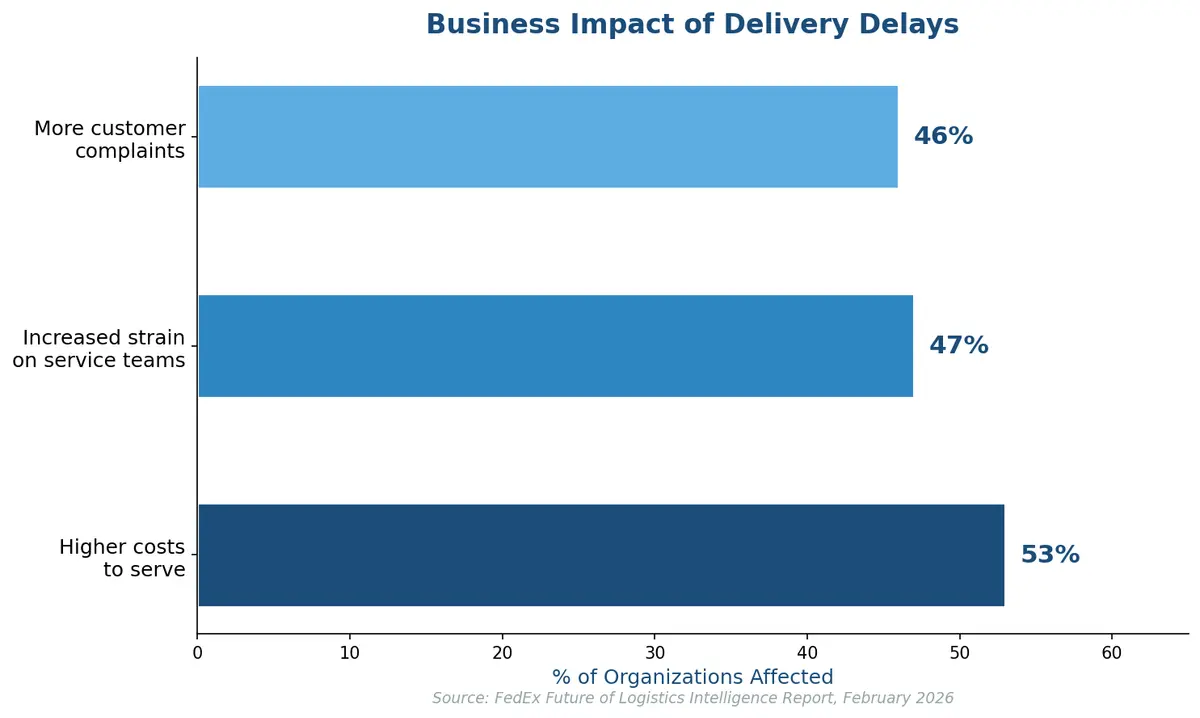

- 53% of organizations report higher costs to serve as a result of delays

- 47% see increased strain on service teams

- 46% face more customer complaints

Limited visibility and delivery delays remain the most common shipping-related complaints. But here's the key insight: consumers don't care whether you can see their package is delayed. They care whether you predicted the delay and rerouted it before they noticed.

Only 22% Have the Data They Need

Perhaps the most revealing finding: only 22% of decision-makers say they have access to all the types of logistics and supply chain data they need. Despite massive investments in tracking technology, the majority of organizations are still working with incomplete pictures.

This isn't a technology problem — it's an integration problem. Shipment tracking, warehouse data, carrier performance metrics, weather patterns, port congestion signals, and customer behavior data all exist in separate silos. Intelligence emerges only when these streams converge.

From Future-Proof to Future-Ready

The report also sounds an alarm about preparedness: only 43% of leaders strongly agree that their logistics systems are future-proof — meaning they can adapt to shifting customer expectations, compliance demands, and market conditions.

The remaining 57% are running systems that work for today's challenges but will buckle under tomorrow's. As Jason Brenner, SVP of Digital Portfolio at FedEx, put it: "Being ready for what's next requires investing in systems that go beyond meeting today's needs. Connected data, analytics, and AI are essential to making that shift."

What Intelligence Actually Looks Like

The shift from visibility to intelligence isn't about buying a new dashboard. It's about fundamentally changing how logistics data flows through an organization:

-

Prediction over detection. Instead of alerting when a shipment is late, intelligent systems forecast delays 24-48 hours before they happen based on carrier patterns, weather, and congestion data.

-

Automated intervention. When a predicted disruption crosses a threshold, the system doesn't just flag it — it triggers rerouting, carrier switching, or proactive customer communication.

-

Cross-modal optimization. Intelligence means understanding that a delayed ocean shipment affects warehouse capacity, which affects last-mile scheduling, which affects the customer promise. One data stream, connected end to end.

-

Continuous learning. Every disruption, every intervention, every outcome feeds back into the model. The system gets smarter with every shipment.

Building the Intelligence Layer

The gap between visibility and intelligence is exactly where modern TMS platforms earn their value. A system that merely tracks shipments is table stakes in 2026. What separates leaders from laggards is the ability to transform raw logistics data into decisions — automatically, at scale, across every mode and every mile.

CXTMS was built for this shift. By integrating carrier data, warehouse operations, customs workflows, and customer commitments into a single intelligence layer, CXTMS helps logistics teams move from watching disruptions to preventing them. Real-time analytics, exception-based workflows, and cross-modal visibility aren't add-ons — they're the foundation.

Ready to close the intelligence gap? Contact CXTMS for a demo and see how integrated logistics intelligence transforms your operations.