The Logistics Talent Crisis of 2026: 60% of Jobs Are Being Reshaped by AI While Only 28% of Workers Are Ready

The logistics industry faces a paradox that defines 2026: automation is eliminating thousands of traditional roles while simultaneously creating a massive skills gap that companies can't fill fast enough. About 60% of logistics jobs are being reshaped by AI and automation, yet only 28% of workers have training that matches these new demands, according to Randstad's workforce analysis. The result is an industry caught between two futures — and the companies that bridge this gap will dominate the next decade.

The Paradox: Fewer Jobs, Bigger Gaps

It sounds contradictory, but the numbers tell a clear story. Automation has displaced roughly 35,000 traditional logistics roles in the past year alone — manual picking, basic data entry, repetitive sorting tasks that robots and AI now handle faster and cheaper. Yet logistics hiring demand remains intense, with warehouse and distribution roles ranking among the top nine most in-demand jobs in the U.S. for 2026.

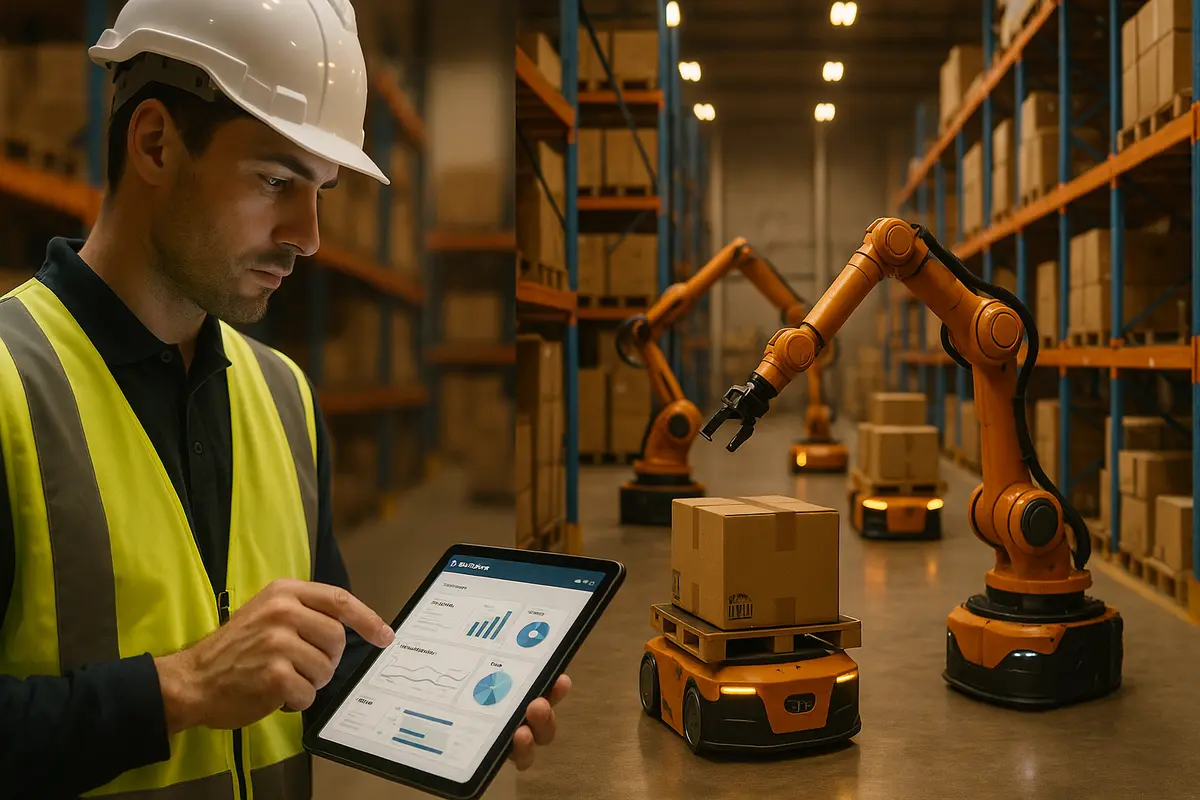

The disconnect? The jobs being created look nothing like the jobs being eliminated. Today's logistics operations need workers who can manage warehouse management systems (WMS), operate automated picking equipment, interpret data-driven forecasting dashboards, and troubleshoot robotic systems. The warehouse associate of 2026 is part technician, part analyst.

The $144 Billion Automation Wave

The scale of investment driving this transformation is staggering. The global logistics automation market is projected to reach $144.78 billion by 2031, growing at a 9.78% CAGR, fueled by rising e-commerce volumes, persistent labor shortages, and corporate sustainability commitments, according to GlobeNewsWire's latest industry report. Meanwhile, the warehouse automation segment alone is growing at 15% CAGR through 2031, with autonomous mobile robots (AMRs), automated storage and retrieval systems (AS/RS), and AI-powered software leading the charge.

This isn't a future scenario — it's happening now. An estimated 75% of large enterprises are planning to implement intelligent robots in their logistics operations. Every one of those deployments creates demand for workers who can program, maintain, and optimize these systems.

An Aging Workforce Meets a Digital Future

The skills gap isn't just about technology adoption. It's compounded by demographics. Many experienced logistics professionals — the supervisors, dispatchers, and planners who kept supply chains running for decades — are approaching retirement. Their institutional knowledge walks out the door with them, and the younger workers entering the field often lack both the operational experience and the digital fluency that modern logistics demands.

When unprepared workers fill these gaps, the consequences cascade quickly. Onboarding cycles stretch from weeks to months. Supervisors spend disproportionate time correcting errors. Safety incidents increase. Turnover rises. The total cost of a bad hire in logistics — including recruitment, training, lost productivity, and safety risks — can exceed $15,000 per position.

The Nine Roles Defining Logistics in 2026

Randstad USA and Lightcast.io identified the most in-demand logistics roles for 2026, and the list reveals exactly where the industry is headed:

- Logistics Coordinators — orchestrating multi-modal shipments across complex networks

- Warehouse Supervisors — managing hybrid human-robot teams

- Supply Chain Analysts — turning data into actionable optimization strategies

- Inventory Managers — leveraging AI forecasting for demand planning

- Fleet Maintenance Technicians — keeping automated vehicles operational

- WMS Administrators — configuring and maintaining warehouse management platforms

- Last-Mile Delivery Planners — optimizing the most expensive leg of shipping

- Robotics Technicians — maintaining AMRs and automated sorting systems

- Compliance Specialists — navigating an increasingly complex regulatory landscape

Notice the pattern: every role requires digital literacy, analytical thinking, or technical maintenance skills. The purely manual logistics job is rapidly disappearing.

Closing the Gap: What Smart Companies Are Doing

The organizations winning the talent war aren't just posting job listings and hoping for the best. They're investing in reskilling programs that transform existing warehouse workers into WMS operators and data-literate supervisors. They're partnering with community colleges and trade programs to build pipelines. And critically, they're choosing technology platforms that lower the skill barrier rather than raise it.

As Logistics Management's analysis of AI in the supply chain emphasizes, this next cycle isn't just about integrating the latest technology — it requires a critical focus on upskilling the workforce and implementing effective change management.

This is where modern TMS platforms make a meaningful difference. When your transportation management system handles route optimization, carrier selection, and shipment tracking through intuitive interfaces and automated workflows, you don't need every team member to be a data scientist. You need competent people who can work with smart tools — and that's a much larger talent pool.

The Bottom Line

The logistics talent crisis isn't going away in 2026. If anything, the automation wave will accelerate the skills mismatch before it resolves it. Companies that invest in workforce development alongside technology adoption will find themselves with a sustainable competitive advantage. Those that don't will keep cycling through undertrained hires, absorbing the hidden costs of the gap.

The future belongs to operations that pair smart people with smart systems — not one or the other.

Struggling to bridge the technology-talent gap in your logistics operations? Contact CXTMS for a demo of how intuitive TMS automation can reduce your workforce skill requirements while improving operational performance.