Blockchain Meets Food Safety: How Distributed Ledger Technology Is Making Farm-to-Fork Traceability a Reality in 2026

Foodborne illnesses cost Americans an estimated $75 billion a year in medical care, lost productivity, and premature deaths, according to USDA researchers. With the FDA's FSMA Rule 204 compliance deadline hitting January 20, 2026, the food logistics industry is racing to deploy technology that can trace contaminated products in seconds rather than days. Blockchain is emerging as the backbone of that transformation.

The $75 Billion Problem That Blockchain Can Solve

The food supply chain has a transparency crisis. When a contamination event strikes, the average food recall takes days — sometimes weeks — to trace products back to their source. During that lag, contaminated food keeps moving through distribution networks, reaching consumers and causing harm.

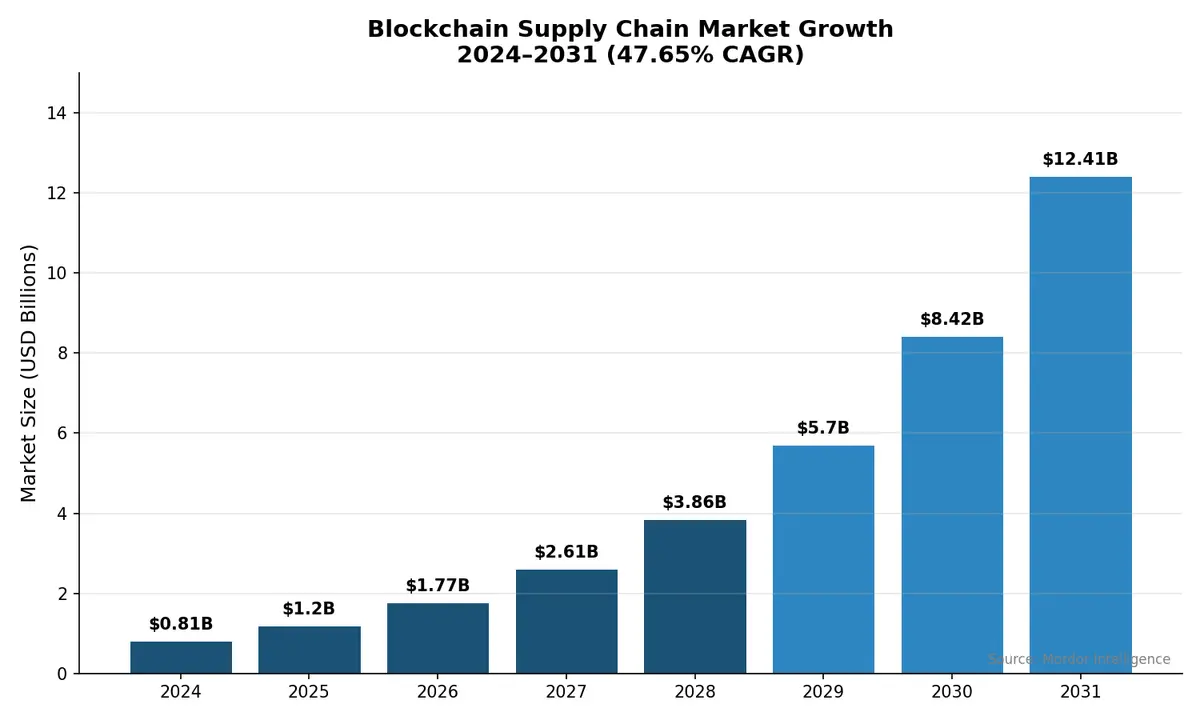

The numbers are staggering. The blockchain supply chain market is projected to grow from $1.77 billion in 2026 to $12.41 billion by 2031, at a CAGR of 47.65%, according to Mordor Intelligence. Meanwhile, the broader food traceability and blockchain solutions market reached $37.37 billion in 2023 and is expected to hit $97.17 billion by 2032, growing at an 11.2% CAGR.

Why the explosive growth? Because regulators, retailers, and consumers are all demanding the same thing: proof of where food comes from, how it was handled, and whether it's safe.

FSMA 204: The Regulatory Catalyst

The FDA's Food Safety Modernization Act Rule 204 — formally titled "Requirements for Additional Traceability Records for Certain Foods" — went into effect in January 2023 with a compliance deadline of January 20, 2026. The rule requires companies that manufacture, process, pack, or hold foods on the Food Traceability List to maintain detailed records linking critical tracking events across the supply chain.

The foods covered include fresh-cut fruits and vegetables, shell eggs, nut butters, fresh herbs, leafy greens, certain cheeses, and specific seafood products — categories responsible for a disproportionate share of foodborne illness outbreaks.

What makes FSMA 204 different from previous regulations is its requirement for Key Data Elements (KDEs) at each Critical Tracking Event (CTE). Every time a covered food is grown, received, transformed, shipped, or sold, specific data must be captured and linked to a traceability lot code. Traditional paper-based or siloed ERP systems struggle with this level of granularity across multiple supply chain partners.

This is precisely where blockchain excels.

How Blockchain Makes Traceability Immutable

Blockchain's core value proposition for food safety comes down to three properties: immutability, transparency, and decentralization.

When a grower records harvest data on a blockchain, that record cannot be altered retroactively. When a distributor logs a temperature reading during transit, it's permanently timestamped. When a retailer receives a shipment, the chain of custody is complete and verifiable by any authorized party.

The Walmart-IBM Food Trust case study remains the industry benchmark. Before blockchain, tracing a bag of sliced mangoes from store shelf to farm took approximately 7 days. After deploying IBM Food Trust on Hyperledger Fabric, that same trace took 2.2 seconds. Walmart subsequently mandated that all direct suppliers of leafy greens upload traceability data to the blockchain platform.

Real-World Impact on Recall Response

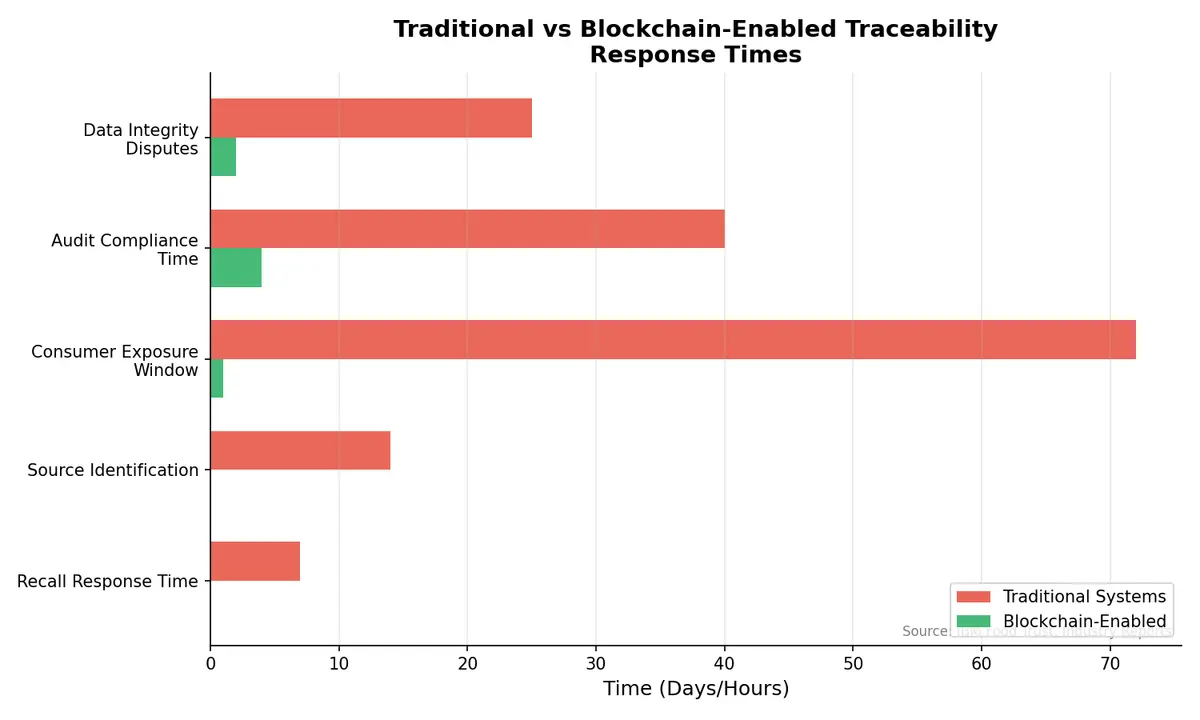

Traditional recall workflows follow a sequential pattern: retailer identifies a problem, contacts the distributor, who contacts the processor, who contacts the grower. Each handoff adds hours or days. During the 2018 romaine lettuce E. coli outbreak, it took the FDA over two months to identify the contamination source in Yuma, Arizona.

With blockchain-enabled traceability:

- Contamination source identification drops from days to seconds

- Targeted recalls replace broad, category-wide withdrawals

- Consumer exposure is minimized because affected lots are pinpointed immediately

- Financial losses shrink dramatically — broad recalls can cost companies $10 million or more per incident

IoT Integration: The Bridge Between Physical and Digital

Blockchain alone doesn't collect data — it stores and verifies it. The real power emerges when blockchain is integrated with IoT sensors that automatically capture conditions throughout the cold chain.

Temperature loggers, humidity sensors, GPS trackers, and RFID tags generate continuous streams of data that are hashed and recorded on the blockchain. If a refrigerated truck's temperature rises above the safe threshold for fresh produce, that deviation is immutably recorded — no one can alter the log after the fact.

This combination addresses one of food safety's biggest challenges: data integrity. In traditional systems, temperature logs can be manually adjusted, timestamps can be fudged, and records can be lost. Blockchain plus IoT creates an audit trail that regulators, insurers, and trading partners can trust.

Beyond Compliance: The Business Case

While FSMA 204 is the immediate driver, forward-thinking companies are discovering that blockchain traceability delivers value far beyond regulatory compliance:

- Premium pricing for provenance: Consumers increasingly pay more for verified organic, fair-trade, or sustainably sourced products. Blockchain provides the proof that justifies the premium.

- Reduced insurance costs: Verifiable cold chain records lower risk profiles, translating to better insurance terms for carriers and shippers.

- Faster customs clearance: Cross-border food shipments with complete, verified traceability documentation move through customs faster, as reported by Food Logistics.

- Waste reduction: Better visibility into shelf life and handling conditions helps reduce the estimated 30-40% of food lost in the supply chain annually.

Challenges and the Road Ahead

Blockchain traceability isn't without hurdles. Interoperability between different blockchain platforms remains a challenge — a grower on one platform needs to share data with a distributor on another. Standards like GS1's EPCIS 2.0 are helping bridge this gap by providing a common data language across platforms.

Cost and complexity also slow adoption among smaller producers. While enterprise platforms have matured, the upfront investment in sensors, integration, and training can be prohibitive for small farms and regional distributors. Industry consortia and government pilot programs are working to lower these barriers.

Data privacy presents another tension. Full supply chain transparency can expose proprietary supplier relationships and pricing. Permissioned blockchains — where access is controlled but records remain immutable — offer a middle ground that most food industry deployments have adopted.

What This Means for Logistics Operators

For shippers, carriers, and 3PLs handling food products, blockchain traceability is no longer optional — it's becoming a requirement for doing business with major retailers and food service companies. The logistics implications are significant:

- Data capture at every touchpoint — receiving, warehousing, cross-docking, and delivery must all generate standardized traceability records

- Cold chain monitoring integration — IoT sensors must feed data into traceability platforms automatically, not through manual logging

- TMS integration — transportation management systems need to connect with blockchain traceability platforms to link shipment records with product-level tracking data

- Training and process changes — warehouse and driver teams need updated procedures for scanning, recording, and verifying traceability data

CXTMS supports these workflows through integrated traceability features that connect shipment-level tracking with product-level compliance data, helping logistics operators meet FSMA 204 requirements without bolting on separate systems.

Navigating food safety compliance across your supply chain? Contact CXTMS for a demo of our integrated traceability and cold chain management capabilities.